Improve process heating system performance to save

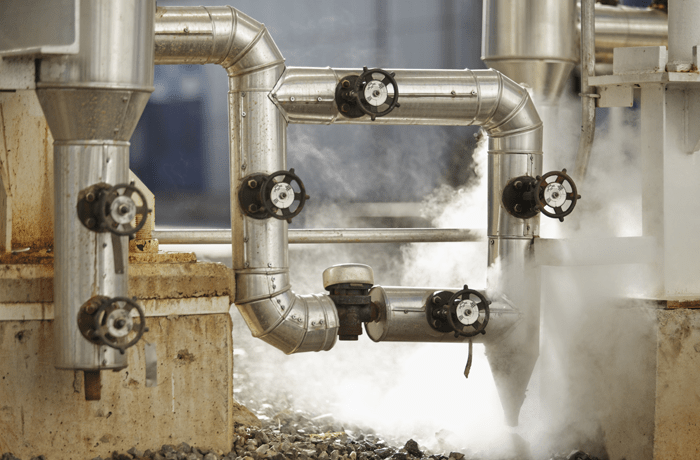

In manufacturing, where raw materials are processed, process heating can account for as much as 15 percent* of total production costs. While most improvements focus on productivity and output, process heating is often overlooked as an opportunity to reduce energy costs.

Our Energy Solutions Advisors can help you discover how incremental changes can generate energy savings—without risk to your core production.

Why improve energy efficiency?

-

Repurpose the heat you’re already paying for.

-

Improve process heating efficiency.

-

Improve workplace productivity.

-

Reduce energy, maintenance and operating costs.

-

Reduce greenhouse gas (GHG) emissions.