Enbridge Gas Utah's hydrogen blending project, ThermH2, was a multi-phase project designed to develop and deploy a natural gas hydrogen blend. Hydrogen, a clean and versatile energy source, has a variety of potential uses to decarbonize multiple industries, including the residential and commercial customers that Enbridge Gas Utah serves. Industry research indicates that when blended with natural gas, modest amounts of hydrogen (up to 5%) can be used in existing infrastructure and appliances without any modifications and the added benefit of reduced emissions.

The first phase of the project took place at the Training Academy in Salt Lake City, Utah in 2021. Enbridge Gas Utah blended 5% hydrogen in a test gas distribution system to confirm copious amounts of industry research on the efficacy and safety of blending hydrogen with natural gas. Throughout a year of rigorous testing, the company was able to confirm this existing research.

Training academy

The next phase of ThermH2 moved to the live system of Delta and surrounding areas of Hinckley, Oasis and Deseret. Enbridge Gas Utah began blending natural gas and hydrogen at a up-to 5% level into the system, which serves approximately 1,800 customers, in March of 2023. In the fall of 2023, a new element to produce green hydrogen on-site was introduced.

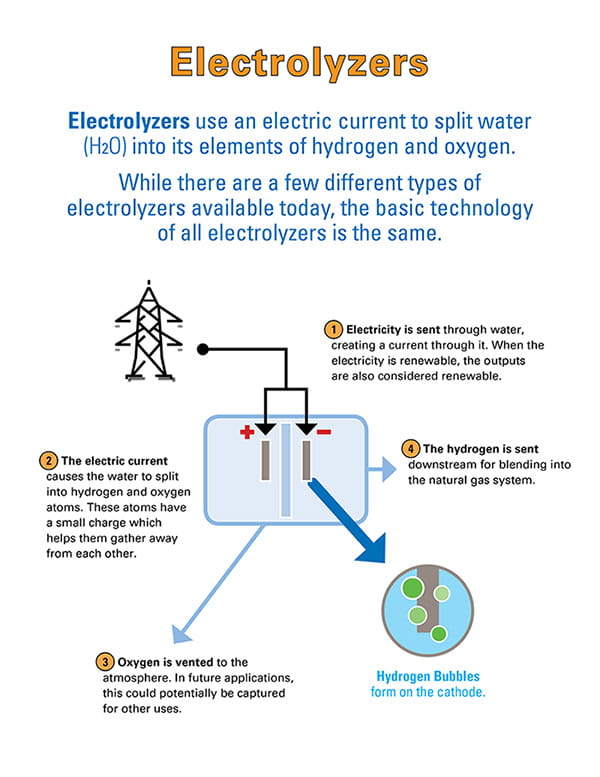

Producing hydrogen on-site through the process of electrolysis was able to provide additional emissions savings for residents in the area—about 110 tons of carbon annually. This is equivalent to planting around 5,000 trees or taking 20 cars off the road! Enbridge Gas Utah celebrated this milestone of introducing an electrolyzer to the project with a ribbon cutting in Delta on October 5, 2023.

Enbridge Gas Utah is one of the few utilities in North America to have successfully blended hydrogen into a live system. Furthermore, they are among one of the first to introduce an electrolyzer into a project to produce hydrogen on site from renewable energy.

As of December 31, 2024, Enbridge Gas Utah announced that it had concluded ThermH2, taking learnings from both phases to inform future strategy. As we reflect on the conclusion of this particular hydrogen blending project, Enbridge Gas Utah was proud to have been successful in accomplishing its objectives, including demonstrating the safety and effective blending of hydrogen into our natural gas system.

We were also appreciative of Millard County, the residents of Delta and the surrounding areas for their support of the program. Collaboration like this is imperative to ensuring we can advance our shared goals.

This program was an example of learning and innovation in action. Enbridge will continue it’s learnings and leverage hydrogen blending pilot projects across the families of companies to continue to look for innovative solutions to demonstrate our commitment to sustainability and to further decarbonize natural gas.